In today’s world our consumption of Carbon Blacks registers approx. 6,800,000 t. The majority are used in rubber applications, hence the name “Rubber Blacks”. Only approx. 550 000t belong to the group of Pigment Blacks.

This group of pigment is produced under pigment relevant production conditions. On the contrary to the Rubber-Black production, the feedstock is based only on specific hydro carbons with low sulphur content.

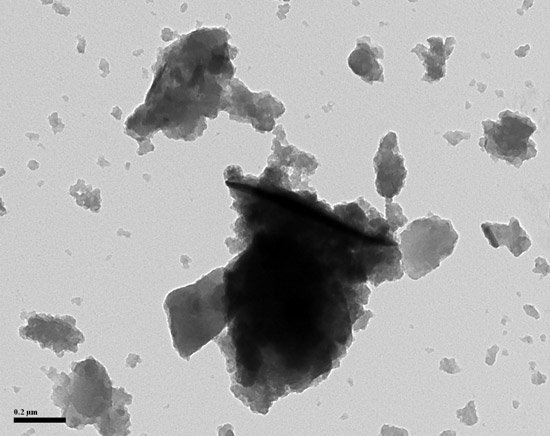

The particle size of Pigment Blacks is the main parameter for adjusting the shade of black in the application. So this should be kept in mind as a production parameter as well as the morphology, called structure, expressed in DBP absorption, and the surface chemistry expressed in pH value and/or volatile content, determined by over 950? .

As aforementioned, the particle size of Pigment Blacks determines the colouristic behaviour. The rule- the smaller the particle size the darker the application – can be transferred to all applications and to all coating systems. We find products for the coating and inkjet industry which are approx. 11nm means 11?, mill-micron up to typical tinting Pigment Black which are approx. 100nm, near by Titandioxyide.

To effectively disperse and stabilise, especially the fine particle size Pigment Blacks, it is necessary to apply, in addition, a specific surface treatment for the black pigment.

This is done by an after-treatment, based on oxidation, to increase the amount of functional groups, mainly COOH-groups. Oxidised Pigment Blacks are easy to find in the wide production list of the Pigment Black producers: Volatile content is higher and the pH-Value is lower, when compared with the basic pigments. The longer the production time for these pigments the more expensive the price, although the performances are better. Water-based coatings show the highest increase of all environmentally friendly coatings. In particular, automotive paint and repair paint producers face the problem of producing like shades in coatings based on binders like PE/CAB, 2C-Acrylics, NC-comb., thermoplastic acrylics, special PE and water based Acrylics and PU systems. To attain the same blackness in all mentioned paints is a real challenge.

For water-based base-coats we need small particle size Pigment Blacks as well, if possible, the one which we use in solvent born coatings or similar. But there is a big difference in terms of the wetting power of the binders.

Is it possible to disperse the pigment in selected solvent born resin with or without small amounts of wetting agents. However, it is essential in waterbased coatings to use special wetting agentsin large proportions. It is also necessary to recognise that the Pigment Black can differ. As mentioned above we have a high density of chemical groups on the surface of the oxidised Pigment Black particle, along with a higher acidity of the pigment. Such pigment black particles require a higher amount of amines to neutralise and to adjust a required pH value of approx.8. For water based coatings, non oxidised Pigment Blacks can be used as an economical alternative

The important factor for success in terms of colour and stabilisation is the type and the amount of wetting agent.There are a wide range of wetting agents which work well. In regards to the amount required, as a guideline 75 to 100% wetting agent, active substance calculated on fine particle size Pigment Black. Pigments with larger particles requires less than that.

Pigment Black concentration in the mill base is also influenced by the particle size of the Black.

15% to 20 % Pigment Black for the mill base is possible.

In the final paint, depending on the thickness of the paint film layer, between 5% and 10% calculated on resin solid are usual. For industrial applications, fine Pigment Blacks as mentioned above, are not necessary. Particle sizes of approx.25 nm are sufficient to fulfil the request from paint users. Dispersion, stabilisation and costs are significantly more favourable compared to the fine particle Pigment Blacks. Powder coatings are much more ‘user-friendly’ with pigment Blacks.

This is because the dispersing energy in the extruders are considerably higher than in other dispersing equipment and once well dispersed there is no space for re-agglomeration or flocculation.

The rule concerning particle size and blackness applies for powder coatings too.

The difference in after-treated Pigments and non treated is often quite small. We regularly do not find any difference in Blackness, it is only the undertone which can change. Fine particle oxidised Pigment Blacks (13nm) produce a bluish undertone which actually makes the onlooker believe that the coating is more black. Only 1% Pigment Black is necessary to produce a powder coating with good hiding power and with less influence on the levelling of the coating.

For tinting purposes large particle size Pigment Blacks, like Lamp Black are easy to handle because of there relatively low tinting strength.

Can we use Pigment Blacks in UV-curing systems?

It is not easy to produce deep black UV -coatings with Pigment Blacks. The main barrier is the particle size. In the literature you find formulations including 25nm-Pigment Black, oxidised and combined with specific high reactive accelerators and selected acrylic resins. That’s the limit insofar as blackness concerns. Better colouristic results are obtainable by using Aniline Blacks.

Pigment Blacks with larger particle sizes which are after-treated, are a good option only for black coatings and UV-curing printing inks.